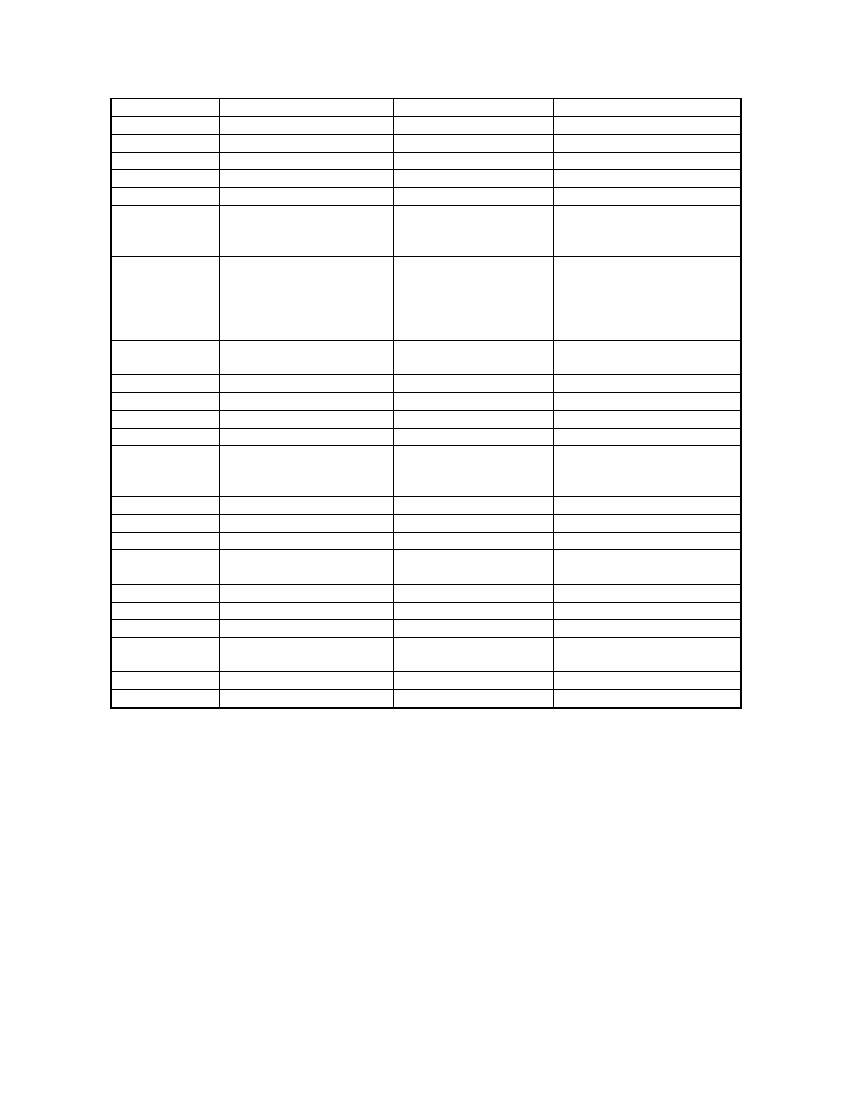

Seal testing (see

chapter 7.1 for

details)

• water in mixing pit

• water in displacement pit

for floating-drum plants:

• water loss < 2%

Gasholder (of

floating- drum

plants only)

Gas valves

Gas pipe

Gas appliances

• water loss > 10% for fixed-

dome plants:

• water loss < 2%

(pressureless) > 10%

• water loss < 5 %

(pressurized) > 10%

•false dimensions,wrong

• grade of steel,

• faulty welds

• faulty painting

• stuck valves

• missing valves

• false water trap

• false gradient

• leak found upon pressure

testing

• poor workmanship

• functional defects

• lengthen the outlet

• alter the elevation of the

a) gas outlet

b) displacement pit

• alteration too much trouble

• alteration too much trouble

• acceptable as is

• repair masonry

• acceptable as is

• repair masonry

• acceptable as is

• repair masonry

• reject gasholder,

build new one

• repair welds

• repaint

• repair or replace

• re-install

• repair leaks

• re-install

• repair or replace

In case of doubt, locate and repair

all defects, even if it seems like a

lot of trouble at the moment;

repairs at a later date would be

more troublesome!

Check carefully; defects most

likely in the gas system

7.2 Plant operation

The operation of a simple biogas plant is relatively uncomplicated. The user must be given all the

information and practical assistance he needs before and during the early phases of plant

operation.

Collecting substrate

The collection of substrate is a simple matter when combined with work that has to be done

anyway, e.g. cleaning the stables. It can be made even easier by arranging for the manure to flow

directly into the mixing pit. Experience shows that it is not a good idea to gather dung from fields,

roads, etc. or to go to the trouble of elaborately chopping up or otherwise preprocessing plant

material for use as substrate. The work involved is usually underestimated, while the motivation is

overestimated.

91