For either design, it is necessary to note that substantial force can be necessary to turn the drum,

especially if it is stuck in a heavy layer of floating scum. Any gasholder with a volume exceeding 5

or 6 m³ should be equipped with a double guide (internal and external).

All grades of steel normally used for making gasholders are susceptible to moisture-induced rusting

both inside and out. Consequently, a long service life requires proper surface protection consisting

of:

- thorough derusting and desoiling.

- primer coat of minium

- 2 or 3 cover coats of plastic/bituminous paint.

The cover coats should be reapplied annually. A well-kept metal gasholder can be expected to last

between 3 and 5 years in humid, salty air or 8-12 years in a dry climate.

Materials regarded as suitable alternatives to standard grades of steel are galvanized sheet metal,

plastics (glass-reinforced plastic/ GRP, plastic sheeting) and ferrocement with a gaslight lining. The

gasholders of waterjacket plants have a longer average service life, particularly when a film of used

oil is poured on the water seal to provide impregnation.

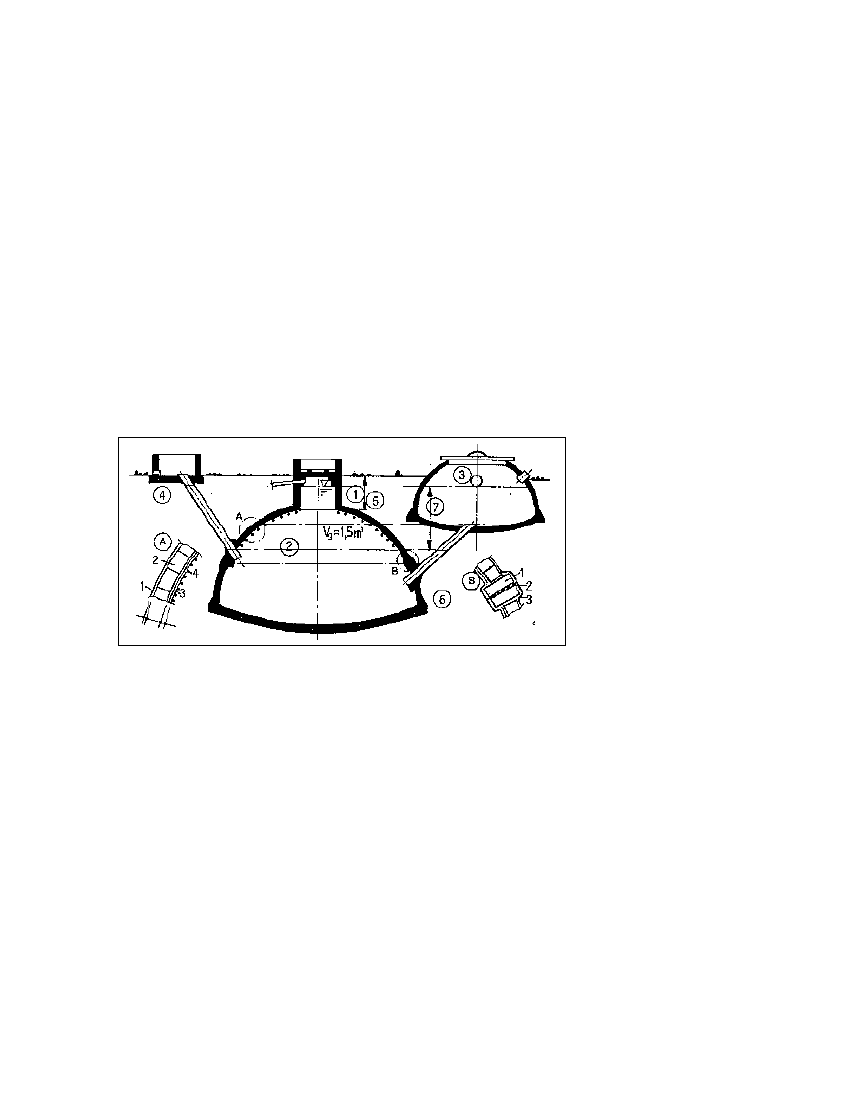

Fig. 5.23: Construction

of a fixed-dome

gasholder. 1 Slurry level

for an empty gasholder

(zero line), 2 Slurry level

for a full gasholder, 3

Overflow, 4 Inlet =

overpressure relief, 5

Earth cover (at least 60

cm), 6 Reinforcing ring

at foot of dome, 7 Max.

gas pressure. A Detail:

wall construction: .1

Outer rendering,.2 Masonry, .3 Twolayer inner rendering, .4 Seal coat. B Detail: rated break point:

.1 Masonry bricks (laid at right angles), .2 Joint reinforced with chicken wire, .3 Seal rendering -

inside and out (Source: OEKOTOP)

Fixed domes

In a fixed-dome plant the gas collecting in the upper part of the dome displaces a corresponding

volume of digested slurry. The following aspects must be considered with regard to design and

operation:

- An overflow must be provided to keep the plant from becoming overfilled.

- The gas outlet must be located about 10 cm higher than the overflow in order to keep the

pipe from plugging up.

- A gas pressure of 1 mWG or more can develop in the gas space, Consequently, the plant

must be covered with enough earth to provide an adequate counterpressure; special care

must be taken to properly secure the entry hatch, which may require weighing it down with

100 kg or more.

59