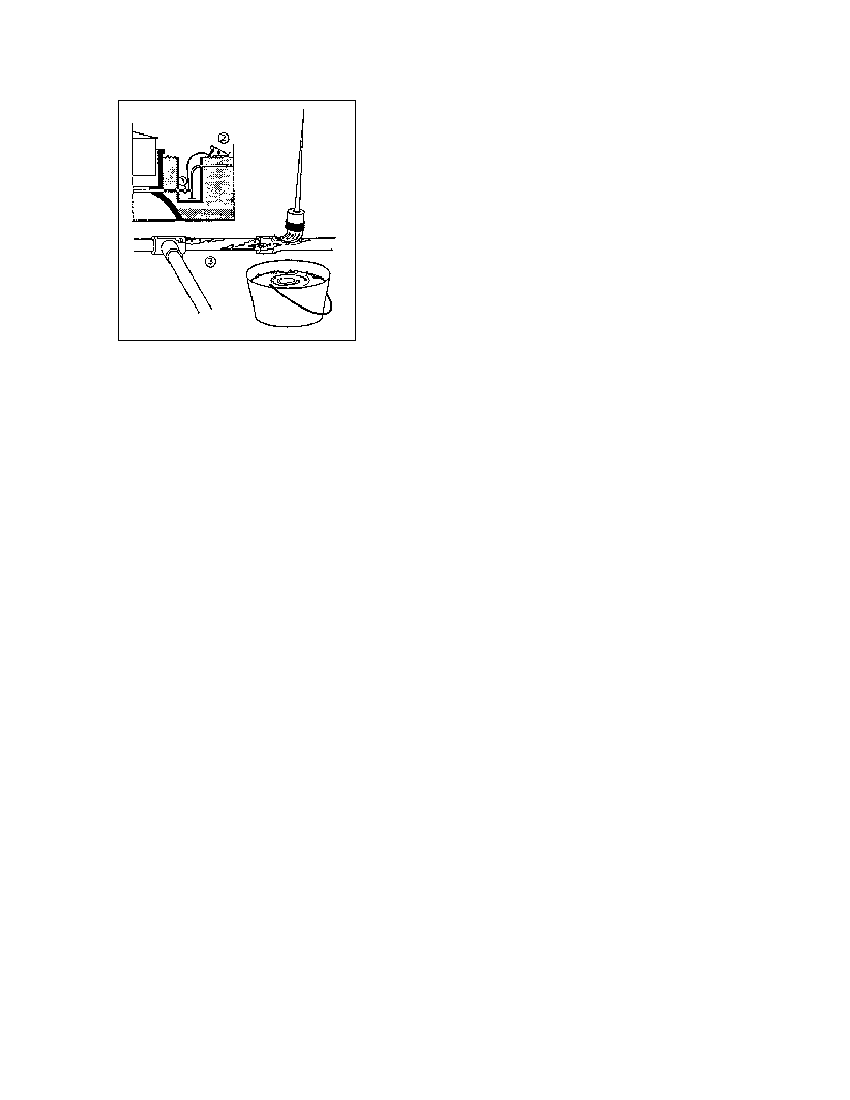

Fig. 7.4: Pressure testing a gas pipe. 1 Close all gas

valves and fill the water trap. Find the maximum pipe

pressure, i.e. how high the pressure in the pipe can go

until the water trap blows off (not more than 50 cmWG). 2

Adjust the test pressure with the aid of a manometer-

equipped test pump or the gasholder (10% below max.

pressure). Check the pressure loss after one day. 3 Use

soapy water to detect leaks. (Source: OEKOTOP)

Pressure testing of the gas pipe

The test must be performed while all gas pipe connections are still accessible. Pressurize the gas

pipe with the aid of a test pump or by placing weights on the gasholder. If there is no noticeable loss

of gas after one day, the pipe may be regarded as gaslight.

Initial filling of the plant

The initial filling for a new biogas plant should, if possible, consist of either digested slurry from

another plant or cattle dung. It is advisable to start collecting cattle dung during the construction

phase in order to have enough by the time the plant is finished. When the plant is being filled for the

first time, the substrate can be diluted with more water than usual.

Starting the plant

Depending on the type of substrate in use, the plant may need from several days to several weeks

to achieve a stable digesting process. Cattle dung can usually be expected to yield good gas

production within one or two days. The breaking-in period is characterized by:

- low-quality biogas containing more than 60% CO2

- very odorous biogas

- sinking pH end

- erratic gas production.

The digesting process will stabilize more quickly if the slurry is agitated frequently and intensively.

Only if the process shows extreme resistance to stabilization should lime or more cattle dung be

added in order to balance with pH. No additional biomass should be put into the biogas plant during

the remainder of the starting phase. Once the process has stabilized, the large volume of

unfermented biomass will give rise to a high rate of gas production. Regular loading can commence

after gas production has dropped off to the intended level.

As soon as the biogas becomes reliably combustible, it can be used for the intended purposes.

Less-than-optimum performance of the appliances due to inferior gas quality should be regarded as

acceptable at first. However, the first two gasholder fillings should be vented unused for reasons of

safety, since residual oxygen poses an explosion hazard.

89