- The loans are not given directly to the beneficiary (plant owners), but channeled through a

biogas extension office.

- The office does not issue the loans in cash, but in the form of materials (cement, metal

gasholders, etc.).

- The material is issued on the basis of construction progress.

- Repayment of the loans is supervised by the biogas extension office with the assistance of the

aforementioned rural development bank.

- A loan guarantee fund into which, say, 10% of each granted loan is fed helps out in case of loan

arrears.

This model involves the following risks:

- The biogas extension office may be overburdened by the task of investigating creditability,

granting loans and helping to monitor repayment of the loans.

- The guarantee fund could dry up due to default on the part of the beneficiaries, or because the

loans were not properly calculated on a break-even basis (inflation, inadequate interest).

Such problems can be overcome in the medium-to-long term by establishing credit unions. That

process, though, demands lots of experience and can normally be expected to by far surpass the

project terms. Credit unions backed by the plant owners could gradually replace the development-

aid part of the lending program. Also, the credit unions could assume responsibility for the

aforementioned loan guarantee fund, thus gaining a say in the control of repayment. In most cases,

that would improve the lending program's reflux quota while helping to establish rural self-help

organizations - a goal that should be viewed as an implicit element of any biogas program.

10. Appendix

10.1 Design calculations and drawings

10.1.1 Floating-drum plants

Design calculation

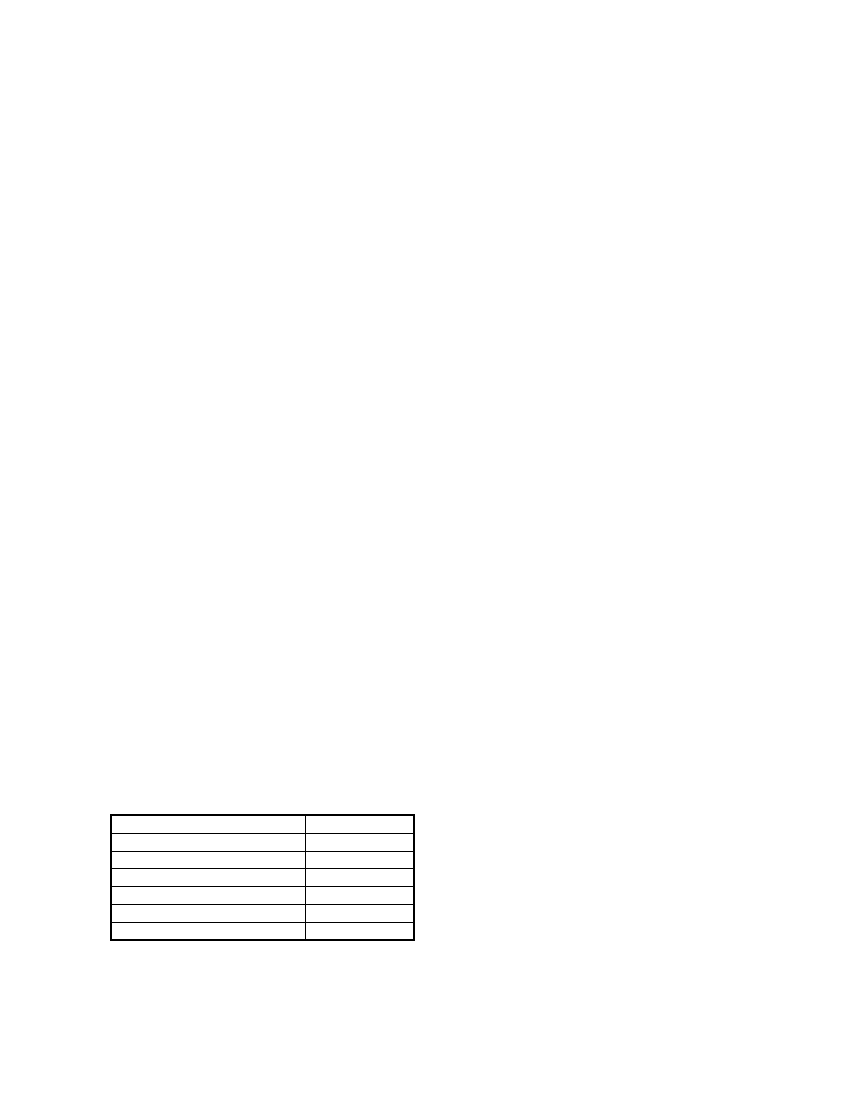

Sizing factors

Daily substrate input, Sd

Retention time, RT

Daily gas production, G

Storage capacity,Cs

Digester volume, Vd

Gasholder volume, Vg

Example

= 115 l/d

= 70 days

= 2.5 m³/d

= 60%

= 8 m³

= 1.5 m³

112