Fixed-dome plants are only recommended in cases where experienced biogas technicians are

available for building them, and when the user is amply familiar with how the plant operates.

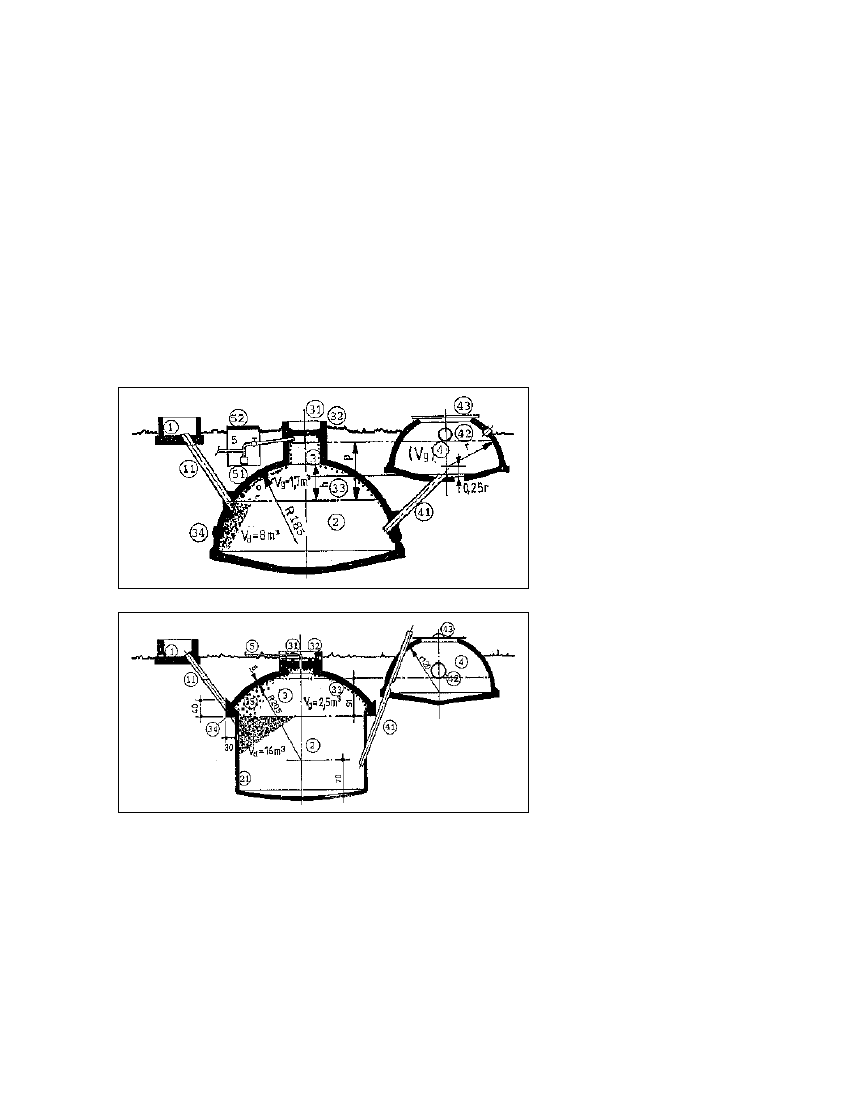

Fixed-dome plant with central entry hatch (cf. fig. 5.10)

The digester has the form of a hemispherical dome which is easy to build. Floating scum can be

removed from the full digester through the central entry hatch.

Fixed-dome plant with suspended dome (cf. fig. 5.11)

Providing a separate foundation for the gas dome yields a statically advantageous, material-saving

configuration that is very well suited for fixed-dome plants of ample size. The dome's foundation

helps prevent cracking due to tensile stress, and the digesting space is made less expensive, since

it can be built of thinner masonry, ferrocement rendering or - in the case of impervious soil - even

left unlined.

Fig. 5.10: Fixed-dome plant

with central entry hatch. 1

Mixing pit, 11 Fill pipe, 2

Digester, 3 Gas holder, 31

Entry hatch, 32 Gas cover, 33

Seal coating, 34 Rated break

ring, 4 Displacement pit, 41

Outlet pipe, 42 Overflow, 43

Cover, 5 Gas pipe, 51 Water

trap, 52 Cover (Source: Sasse

1984 / BEP Tanzania 1987 /

OEKOTOP)

Fig. 5.11: Fixed-dome plant

with suspended dome. 1

Mixing pit, 11 Fill pipe, 2

Digester, 21 Digester

rendering, 3 Gas holder, 31

Entry hatch, 32 Cas cover, 33

Seal coating, 34 Dome

foundation, 35 Dome masonry,

4 Displacement pit, 41 Outlet

pipe, 42 Overflow, 43 Cover, 5

Gas pipe (Source: BEP

Tanzania 1987/ OEKOTOP)

5.3.3 Other types of construction

In addition to the two most familiar types of biogas plant, as described above, a selection of special-

purpose and otherwise promising designs are briefly presented below.

48