- modifying the combustion-air supply, particularly if a combustion-air controller is provided -

increasing the size of the jet openings (avoid if possible) The aim of all such measures is to

obtain a stable, compact, slightly bluish flame.

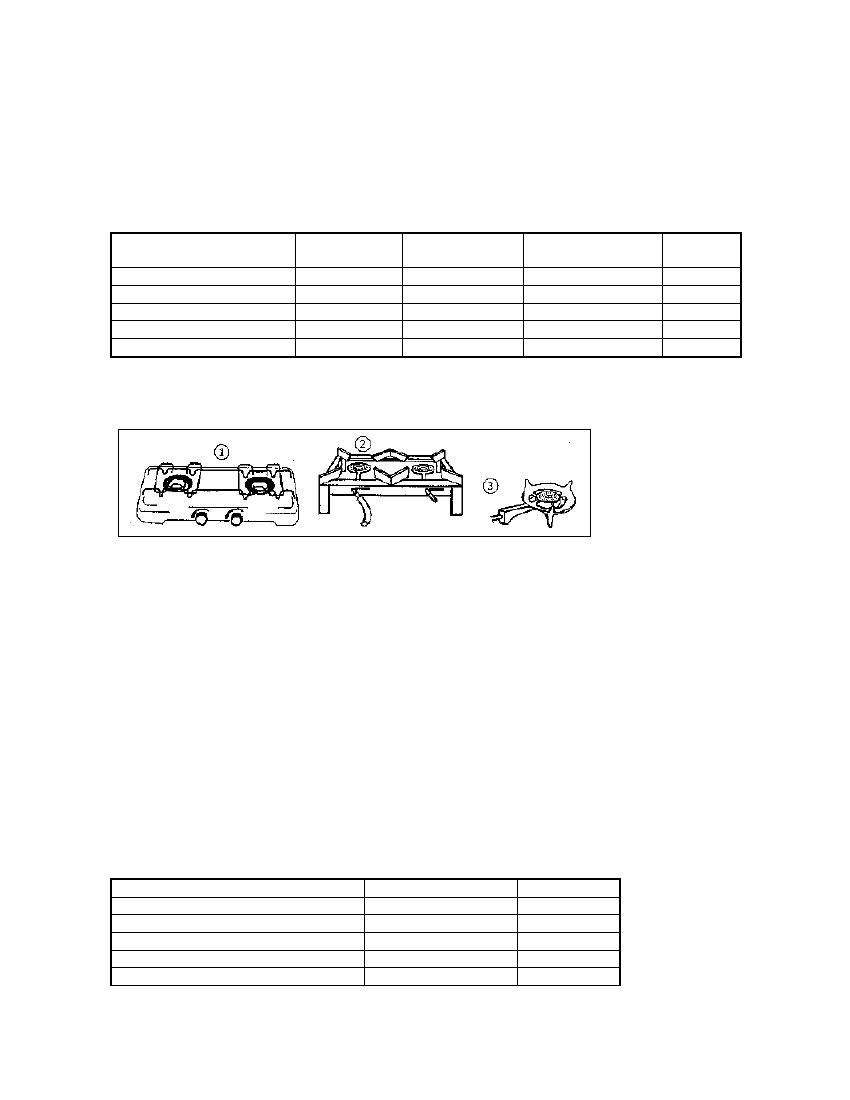

Table 5.16: Comparison of various internationally marketed biogas burners (Source:

OEKOTOP, compiled. from various sources)

Type of burner¹

Peking No. 4/PR China (3)

Jackwal/Brazil (1)

Patel GC 32/ludia

Patel GC 8/India

KIE burner/Kenya (2)

Number of

flames

1

2

2

1

2

Gas

consumption

200 l/h

2 X 1501/h

2 X 2501/h

2301/h

?

Burning

properties

+

++

o

+

+

Handling

o

+

++

++

++

++ very good +good o average

1 Number of burner shown in figure 5.31

Fig. 5.31: Various types of biogas burners. 1 2-flame lightweight burner (2 X 1501/h), 2 2-flame

stable burner (2 X 2501/h), 31-flame burner (200 I/h) (Source: OEKOTOP)

Gas cookers/stoves

Biogas cookers and stoves must meet various basic requirements:

- simple and easy operation

- versatility, e.g. for pots of various size, for cooking and broiling

- easy to clean

- acceptable cost and easy repair

- good burning properties, i.e. stable flame, high efficiency

- attractive appearance

A cooker is more than just a burner. It must satisfy certain aesthetic and utility requirements, which

can vary widely from region to region. Thus, there is no such thing as an all round biogas burner.

Field data shows that 2-flame stable burners are the most popular type (cf. fig. 5.31).

Table 5.17: Biogas consumption for cooking (Source: OEKOTOP, compiled from various

sources)

To be cooked:

11 water

51 water

31 broth

1/2 kg rice

1/2 kg legumes

Gas consumption

30-40 l

110-140 l

~60 l/h

120-140 l

160-190 l

Time

8-12 min

30-40 min

~40 min

~60 min

68