Table 5.11: Quality ratings for various dome-sealing materials (Source: OEKOTOP)

Material

Cold bitumen

Bitumen with alu-foil

Epoxy resin

Paraffin

++ very good

Processin

g

++

+

++

+

+ good

Seal

Durability

o

++

+

o

o satisfactory

o

+

++

o

- problematic

Costs

++

+

-

++

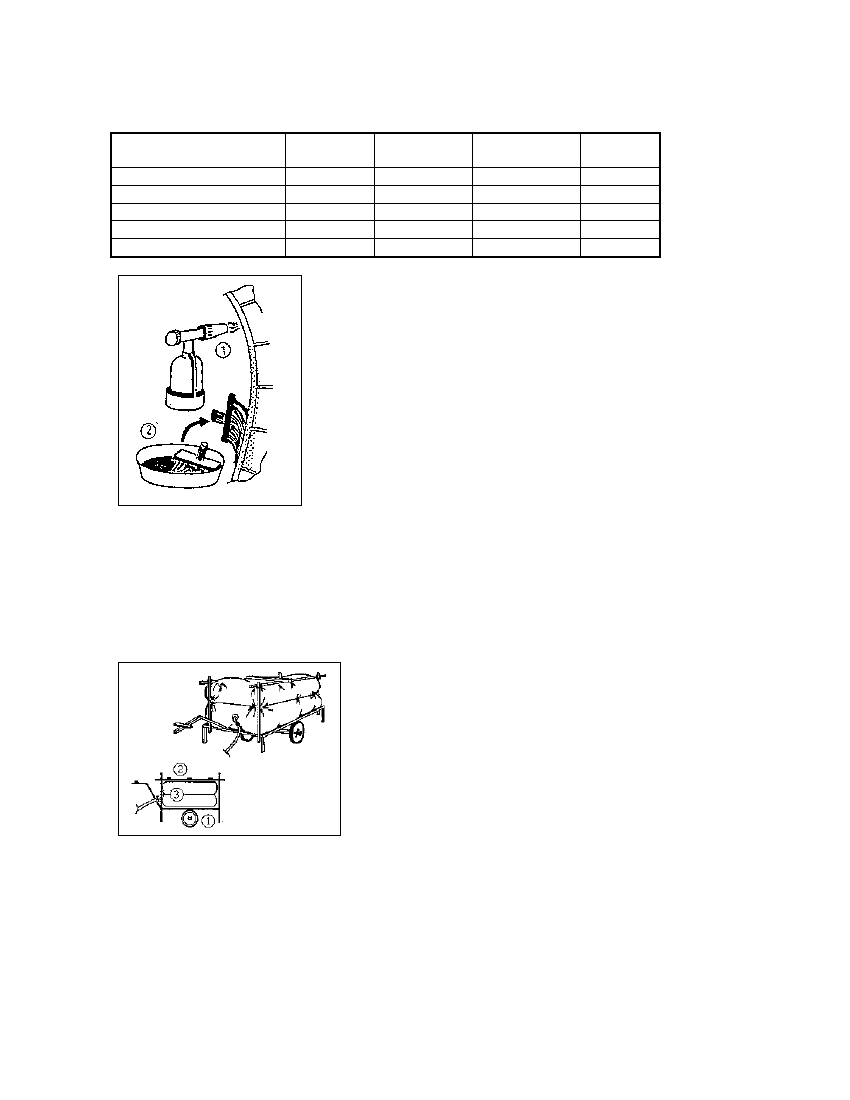

Fig. 5.25: Sealing the masonry with paraffin. 1 Heat wall to 60 - 80

°C with soldering torch, 2 Apply hot (100 °C) paraffin (Source:

OEKOTOP/ BEP Tanzania)

Plastic gasholders

Gasholders made of plastic sheeting serve as integrated gasholders (cf. chapter 5.3.3: earth pits),

as separate balloon/bag-type gasholders and as integrated gas-transport/ storage elements.

For plastic (sheet) gasholders, the structural details are of less immediate interest than the question

of which materials can be used. Table 5.12 (p. 74) surveys the relative suitability of various

commercial grades of plastic sheeting.

Fig. 5.26: Separate, mobile, plastic-sheet gasholder. 1 Cart

for gasholder volumes of 1 m³ and more, 2 Stabilizing

weights and frame, 3 Reinforced plastic gasholder (Source:

Wesenberg 1985)

Separate gasholders

Differentiation is made between:

- low-pressure, wet and dry gasholders (10 - 50 mbar) Basically, these gasholders are identical

to integrated and/or plastic (sheet) gasholders. Separate gasholders cost more and are only

worthwhile in case of substantial distances (at least 50-100 m) or to allow repair of a leaky

fixed-dome plant.

61