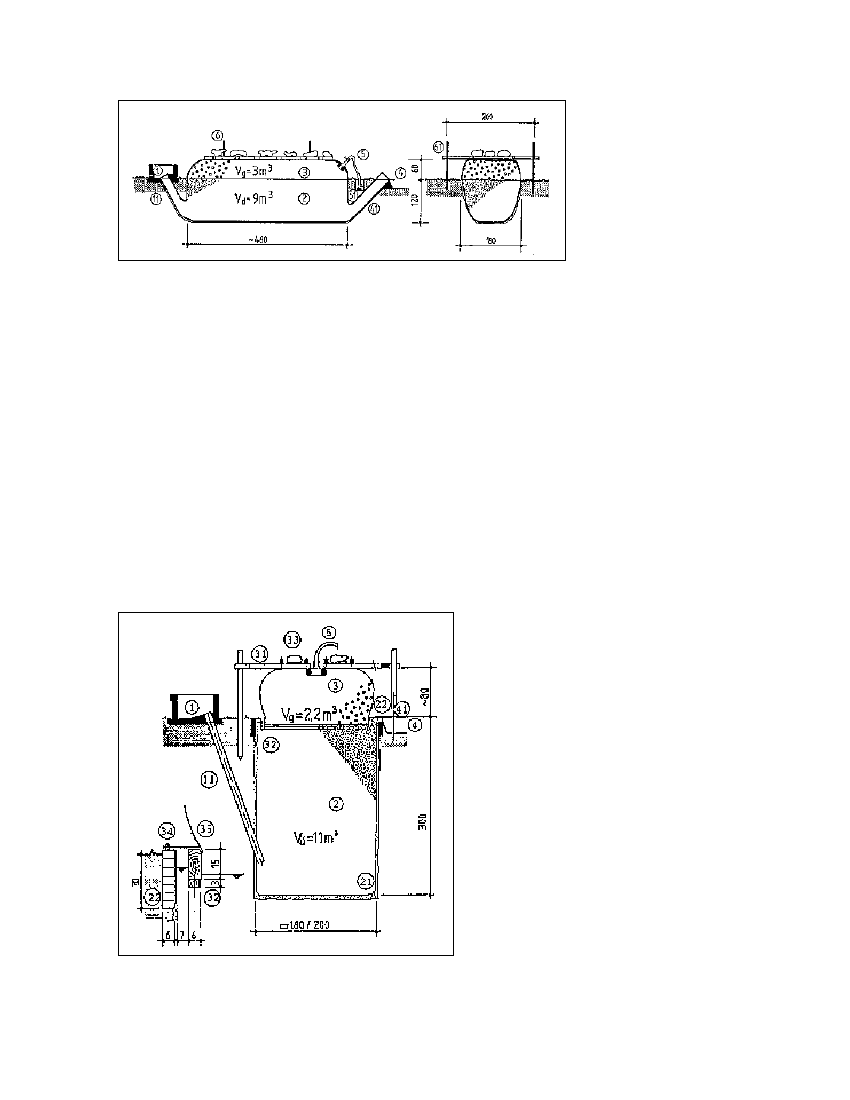

Fig. 5.12: Horizontal

balloon-type

biogas

plant. 1 Mixing pit, 11

Fill pipe, 2 Digester, 3

Gasholder, 4 Slurry

store, 41 Outlet pipe, 5

Gas pipe, 51 Water trap,

6 Burden, 61 Guide

frame

(Source:

OEKOTOP)

Inflatable balloon plants (cf. fig. 5.12)

Inflatable biogas plants consist of a heatsealed plastic or rubber bag (balloon), the top and bottom

parts of which serve as the gasholder and digester, respectively. The requisite gas pressure is

achieved by weighting down the bag. Since the material has to be weather-resistant, specially

stabilized, reinforced plastic or synthetic caoutchouc is given preference. The useful life amounts to

2 - 5 years.

Advantages: Standardized prefabrication at low cost; shallow installation suitable for use in areas

with a high groundwater table.

Drawbacks: Low gas pressure requires extra weight burden, scum cannot be removed. The plastic

balloon has a relatively short useful life, is susceptible to damage by mechanical means, and

usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged

balloon.

Inflatable biogas plants are recommended, if local repair is or can be made possible and the cost

advantage is substantial.

Fig. 5.13: Earth-pit plant with plastic-sheet

gasholder. 1 Mixing pit, ll Fill pipe, 2

Digester, 21 Rendering, 22 Peripheral

masonry, 3 Plastic-sheet gasholder, 31

Cuide frame, 32 Wooden frame, 33

Weight, 34 Frame anchorage, 35 Plastic

sheeting, 4 Slurry store, 41 Overflow, 5

Gas pipe (Source: OEKOTOP)

49