GRAVITY GOODS ROPEWAY

Rope laying

Points to remember while laying the wire ropes

along the alignment:

Clear the bushes, trees or other obstacles

before pulling the ropes

Follow the marked alignment while

transporting the ropes from bottom station

to the upper station (leave the mark at the

alignment while surveying)

Do not uncoil ropes from a stationary coil

or reel. Use rotating wheel, drum or disk

to avoid kinking

First, pull the haulage rope along the

alignment then pull the track rope

If there is a river or stream across the

route, do not dip the rope into water

while hoisting

7.7.2 Sag checking

The designed sag can be accurately provided by

marking the saddle points and centre point of

rope before installation.

As the rope inclination is directly proportional to

the sag provided, the required sag can also be

provided by monitoring the rope inclination at

upper saddle (β).

7.7.3 Rope terminals

A) Terminals with drums in concrete

Ropes may be anchored directly into the

foundations with the help of bollards (drums

made out of reinforced concrete) and secured

with bulldog grips. The ropes should be wounded

three times around the drum in order to reduce

the tensile force and to be secured. The minimum

diameter of the drums should be 0.4 m.

B) Terminals with sockets

Sockets should be manufactured from structural

steel (standard quality) conforming to IS 226

1975 specifications having a tensile strength

of 420 to 640 N/mm2 and normalised after the

completion of machining operations and hot dip

galvanised.

Socketing should be made with pure zinc according

to IS 3937 1974 (Part 1), recommended for

socketing of wire ropes.

Sockets can be used as an alternative to thimbles

and bulldog grips for all rope anchorages.

C) Terminals with thimble and bulldog grips

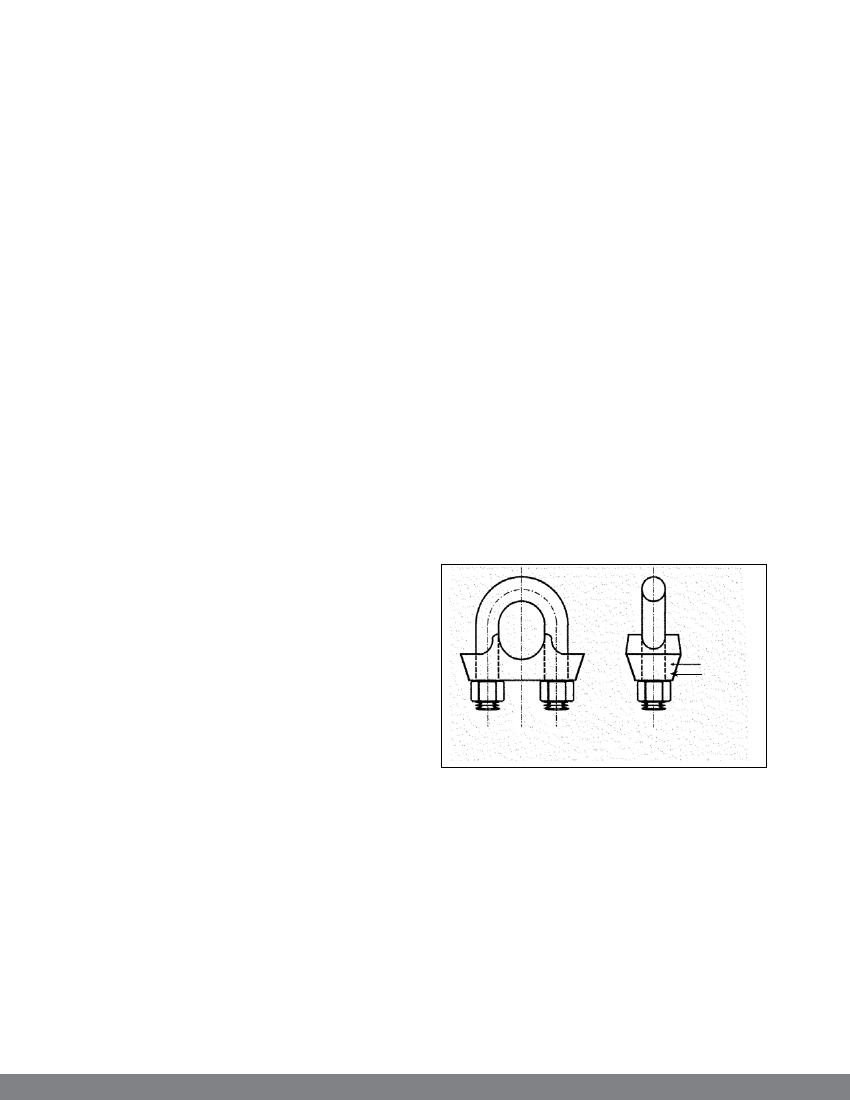

Bulldog grips

These should conform to IS 2361 1970

specifications. The bridges must be drop forged and

suitably scored to grip around strand rope of right

hand lay having six strands. Bridges, eurobonds

and nuts should be hot dip galvanised.

Bulldog grips, when properly applied, afford

a simple and effective mechanical means of

securing the ends of wire ropes, but have to be

inspected after some loadings.

bridge

bulldog grip

Figure 25: A bulldog grip

Thimbles

Thimbles are of open type, conforming to

specifications of IS 2315 1978. They must be

forged and hot dip galvanised. The pin must support

the thimbles. They are necessary to give lateral

support to the strands of the rope at the bend.

The bridge of the grip must be fitted on to the

working part of the rope and the U bolt on to the

rope tail. The first grip must be fitted as close as

possible to the thimble. Grips should be spaced

38