GRAVITY GOODS ROPEWAY

on the adopted mixing method. There are usually

two methods of concrete mixing mechanical

mixing and manual mixing. As mechanical mixing

is not possible in remote ropeway sites, concrete

mixing is done manually. Concrete may be mixed

using ordinary hand shovels. The consistency and

uniformity of the concrete mix will depend on the

degree of control and experience of the labour

force. Hand mixing method is very unlikely to

produce uniform quality concrete but this method

is satisfactory for gravity ropeway as the concrete

volume required is less.

7.5.4 Casting of concrete

Casting of concrete has to be done immediately

after mixing but in unavoidable situation it can

be casted within two hours of mixing to avoid

setting of the concrete mix. Before casting the

concrete, the formwork should be thoroughly

cleaned. In construction joints, the previously

concreted surfaces must also be cleaned with

water. Loose stones and debris must be removed.

Ideally, the surface should be rough, clean and

damp. The concrete can be transferred from

the mixing place manually in steel dishes and

should be placed in the excavations in such a

way that the concrete does not fall freely from

heights of more than one and a half metre.

Concrete falling from greater heights leads to

the segregation of the aggregates and a loss in

consistency of the concrete mix. Guiding chutes

should be used when it has to be poured from

higher than recommended levels. The concrete

should be vibrated during the placing. Usually

a electric vibrator is used, but in remote places

where basic infrastructures like electricity, fuel

and generators lack, uniform hand tamping can

be done using pieces of timber or steel rods.

To attain good compaction and an acceptable

concrete quality, a high degree of control is

required. While compacting, the thickness

of the concrete layers should be 150 to 200

mm and the layers be tamped until an air tight

surface is achieved.

7.5.5 Curing concrete

When concrete sets, it releases a lot of heat. The

chemical reactions take place when concrete

sets are exothermic, where the concrete dries

quickly and may develop shrinkage cracks. The

concrete therefore needs to be kept wet until the

setting is complete.

7.5.6 Prescribed concrete mixes

In most of the cases, there is a lack of expertise

in the rural areas to calculate a proper concrete

mix design in which case prescribed mixes

commonly used in the construction industry

may be adopted. The mixes do not give an

accurate grade of concrete but the results are

generally accepted being within the reasonable

target strengths. The commonly used mixes are

specified in terms of fixed volumes.

The grades of concrete and mix prescribed for

the ropeway are given in table 5:

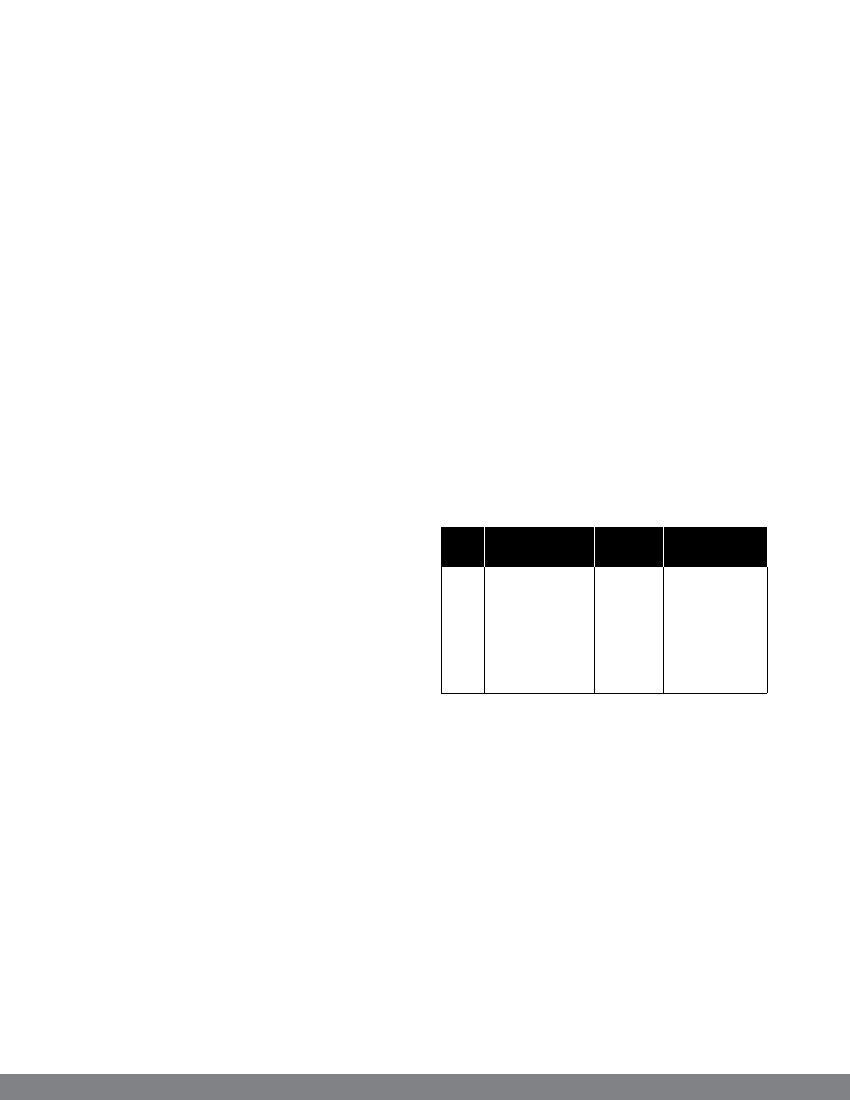

Table 5: Grades of concrete and its proportions

Grade Classification

Mix

Use

proportions

M10 Low strength 1:3:6

M15 Standard concrete 1:2:4

Plumb

concrete,

floor

Tower,

Column, Post,

and sheave

anchorage

Concrete should comply with the following IS

codes:

IS 456-1978 Plain and reinforced concrete

IS 269-1989 Ordinary Portland cement

IS 383-1970 Coarse and fine aggregate

36