design

diameters. Before cutting off the sample rope,

the test sample should be securely seized with

wire of 5 rope diameters in length to prevent the

slackening of the test length.

Both end of the sample should be capped with

white metal cap (zinc caps) and the sample be

tested on a suitable tensile test machine until

the breakage is obtained. The testing procedures

should comply with relevant Indian code.

3.1.10 Ordering wire ropes

Wide ranges of ropes are manufactured for various

purposes or applications. The details of wire ropes

and their application requirements should be

clearly mentioned while placing the procurement

order for the rope. The order should contain the

following information:

The length of the rope

The rope construction (type of lay, method of

stranding, type of core)

The rope type (seale, warrington)

The rope diameter

The size of the wire (diameter, metallic area

and other dimensions)

The tensile strength of wire

The rope weight per metre

The grade of the galvanisation

Lubrication

Preforming/non preforming

Elongation (pre stretched/non pre stretched )

Rope/wire tests and certification

Working condition

While placing an order for a rope, an extra

allowance of length should be considered

for anchoring and laying, and transporting or

transferring. Manufacturer’s test certificate

should be obtained from the manufacturer at the

time of rope delivery.

3.2 Mechanical Components

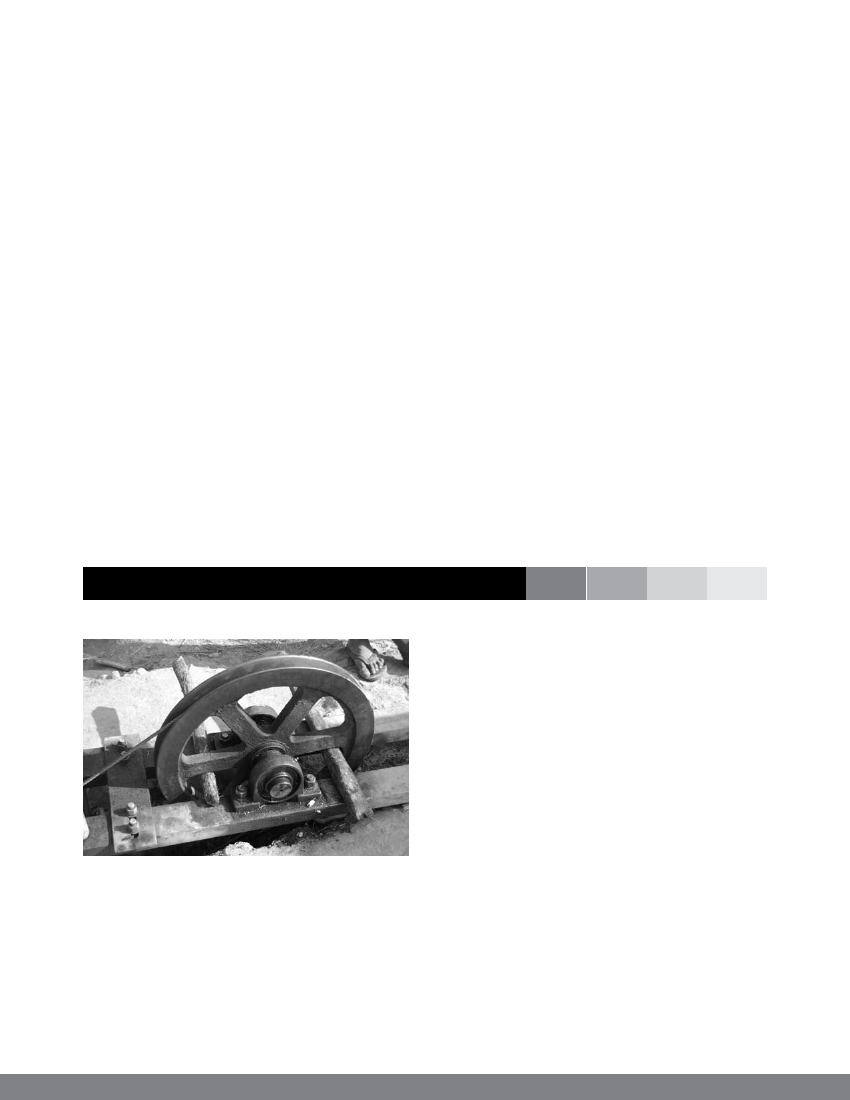

Photo 2: Sheavecast Iron

3.2.1 Sheave

Diameter of driving sheave: The diameter should

not be less than 80 times that of the size of wire

rope and 800 times that of the outer wire of the

wire rope to prevent the sharp bending of the wire

rope at the sheaves. For example, if the hauling

rope diameter is 9 mm, the diameter of the sheave

should not be less than 720 mm (0.72 m). This

is detrimental to the life of the hauling wire rope.

The radius of the sheave groove rg=0.53 d

A larger groove diameter leads to flattening of the

rope while a small groove diameter causes it to

be pinched. The sides of the groove should be

sloped at an inclusive angle of 60 degrees so

that the ropes rest on the groove by one third

of its circumference without touching its sides.

Other requirements:

Steel shafts with keys for mounting grooved

pulley of required diameter

Self aligning deep groove ball bearings for

the shafts

23