Underground Water

Underground water features in all three steps of biogas implementation:

• During planning, the site selection and design of the digester can eliminate most of

the problems caused by groundwater and threats to groundwater.

• During construction, groundwater can be a nuisance, effecting additional costs. But it

is during construction, that serious leakage can be avoided.

• During operation, little can be done but to monitor the quality of water and to avoid

surface spilling.

By positioning the biogas plant and the well, a great deal of drinking water safety can be

achieved. First, the distance should be at least 30 m, second, the biogas plant should be

downstream of surface- and groundwater flows and third, the well should be above the

biogas unit to avoid contamination through surface spilling.

During construction, ground water must be drained. An empty biogas digester can develop

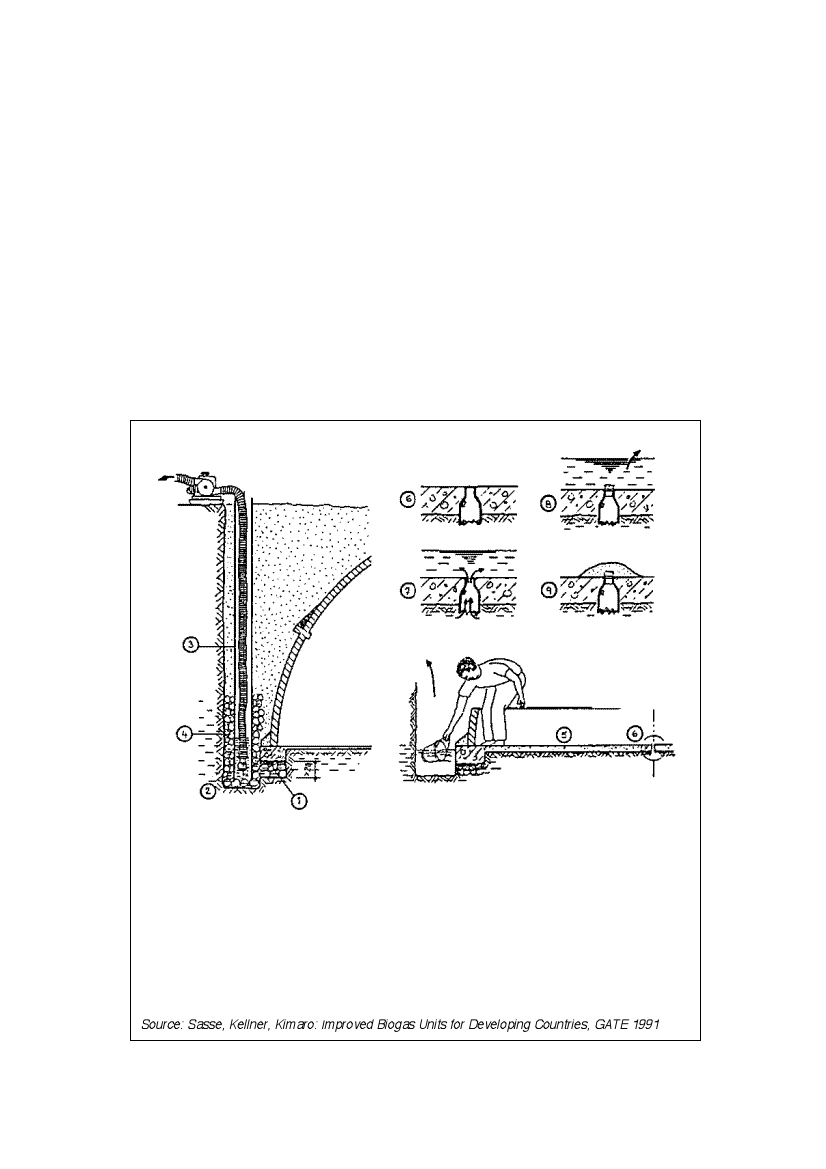

such buoyancy, if surrounded by water, that the whole shell is lifted. The figure below

illustrates some simple techniques how to deal with ground water during construction of

small biogas plants.

Figure 41: Dealing with ground water during construction: The foundation rests on a stone

packing (1) to drain the water into the pump-sink (2). A layer of gravel prevents blockage of

the drain. A vertical pipe (3) allows pumping even when back-filling has be done. The lower

part of the pipe is surrounded by a stone packing (4). If the ground water is only slightly

higher than the digester bottom or if no pump is available, the construction must be

flooded. The floor must be of solid concrete (5). Water must be kept away until the outer

wall has reached above the ground water table and has been plastered from the outside.

Several bottles without bottoms are placed into the concrete (6). When scooping of water

has stopped, ground water passes through the bottle and floods the floor (7). After

completing the masonry work and covering the dome with soil, the bottle is closed and

water might be taken off the digester bottom (8). The cap of the bottle is covered with

cement mortar (9). In case of high ground water table a conical or bowl-shaped solid

concrete slab is required.

Source: Sasse, Kellner, Kimaro: Improved Biogas Units for Developing Countries, GATE 1991

63