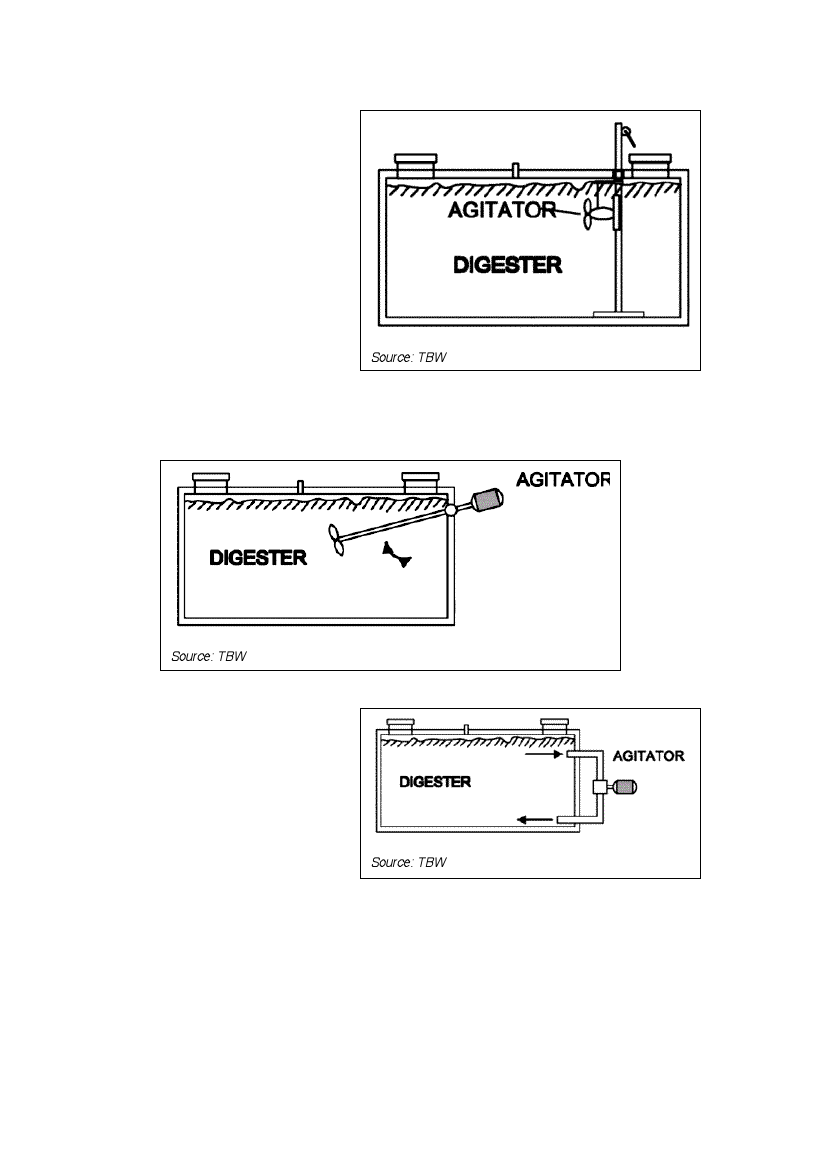

Shaft-driven rotors

The mode of operation of a shaft-

driven rotor is comparable to that

of a submerged engine with rotor,

only that the rotor is driven via

shaft by an engine or by hand.

The shaft should be movable in

height and in angle to allow a

mixing throughout the digester.

The shaft should be long enough

to reach both swimming and

sinking layers.

The rotor shaft can be inserted in

two principle ways:

• Through the digester wall

below the slurry level with

water-tight sealing

• Through the gas-holder

with gas-tight sealing

Figure 35: Submerged motor with rotor stirring

Source: TBW

Figure 36: Shaft-driven rotor

Source: TBW

Hydraulic mixing

With a strong pump the whole

substrate can be put in motion,

provided the intake and outlet of

the pump are placed in a way that

corresponds with the digester

shape. These pumps are often

placed in a central position to cater

for other tasks.

Figure 37: Hydraulic mixing

Source: TBW

Mixing through injection of biogas

A piping system with gas-jets is installed at the bottom of the digester. The raising biogas

bubbles provide a gentle mixing of the substrate. The main problem with these systems is

slurry entering into the piping system. This can be avoided by fixing pieces of elastic hose-

pipe with stainless steel hose coupling to the jets.

Hydraulic mixing by injecting biogas should not be used if the formation of swimming layers

is a prevailing problem. Gas bubbles attach themselves to larger fibrous particles and lift

them upwards, thus speeding up the formation of a swimming layer. Chopping up the

substrate by means of chopper pumps or chopper rotors can only partly solve this problem.

57