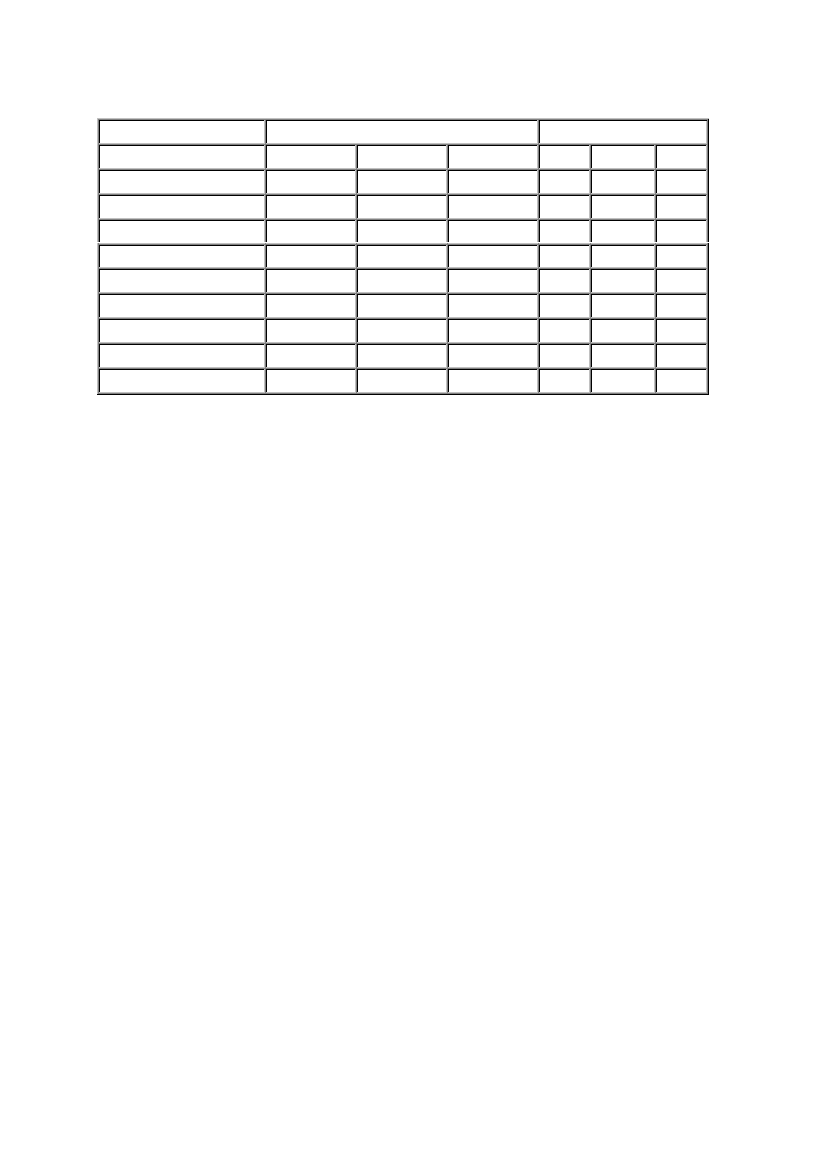

Table 3: Appropriate pipe diameter for different pipe lengths and flow-rate (maximum

pressure loss < 5 mbar)

Galvanized steel pipe

PVC pipe

Length [m]:

20

60

100

20 60

100

Flow-rate [m3/h]

0.1 1/2" 1/2" 1/2" 1/2" 1/2" 1/2"

0.2 1/2" 1/2" 1/2" 1/2" 1/2" 1/2"

0.3 1/2" 1/2" 1/2" 1/2" 1/2" 1/2"

0.4 1/2" 1/2" 1/2" 1/2" 1/2" 1/2"

0.5 1/2" 1/2" 3/4" 1/2" 1/2" 1/2"

1.0 3/4" 3/4" 3/4" 1/2" 3/4" 3/4"

1.5

3/4" 3/4" 1"

1/2" 3/4" 3/4"

2.0 3/4" 1" 1" 3/4" 3/4" 1"

The values in this table show that a pipe diameter of 3/4" is suitable for flow rates up to

1.5 m3/h and distances up to 100 m (PVC pipe). Therefore one could select the diameter

of 3/4" as single size for the hole piping system of small biogas plants. Another option is to

select the diameter of l" for the main gas pipe and 1/2" for all distribution pipes to the gas

appliances.

Lay-out of the piping system

PVC can be used for all underground pipes or pipes that are protected against sun light and

out of the reach of children. For all parts of the piping system that are above ground one

should install galvanized steel pipes. Therefore it is recommended to use l" G.I. steel pipes

for the visible part of the piping system around the biogas digester. For the main pipe one

uses l" PVC pipe placed underground. The distribution pipes should be 1/2" G.I. steel pipes

or PVC pipes, depending whether they are installed above or under the wall plastering. But

even though G.I. pipes are less susceptible to damage, placing them underground should

always be the preferred solution.

PVC pipes have to be laid at least 25 cm deep underground. They should be placed in a

sand bed and be covered with sand or fine earth. One should carefully back-fill the ditches in

order to avoid stones lying directly above the pipe.

When the piping is installed - and before refilling the ditches - it has to be tested for possible

gas leakage. This can be done by pumping air into the closed piping system up to a pressure

that is 2.5 times the maximum gas pressure of the biogas plant. If pressure loss occurs within

few hours, every joint of the piping system has to be checked with soap water. Soap-bubbles

indicate any leakage of gas.

Water traps

Due to temperature changes, the moisture-saturated biogas will form inevitably condensation

water in the piping system. Ideally, the piping system should be laid out in a way that allows

a free flow of condensation water back into the digester. If depressions in the piping system

can not be avoided, one or several water traps have to be installed at the lowest point of the

depressions. Inclination should not be less than 1%.

Often, water traps cannot be avoided. One has to decide then, if an ’automatic’ trap or a

manually operated trap is more suitable. Automatic traps have the advantage that emptying -

which is easily forgotten - is not necessary. But if they dry up or blow empty, they may cause

heavy and extended gas losses. In addition, they are not easily understood. Manual traps are

simple and easy to understand, but if they are not emptied regularly, the accumulated

condensation water will eventually block the piping system. Both kinds of traps have to be

installed in a solid chamber, covered by a lid to prevent an eventual filling up by soil.

49