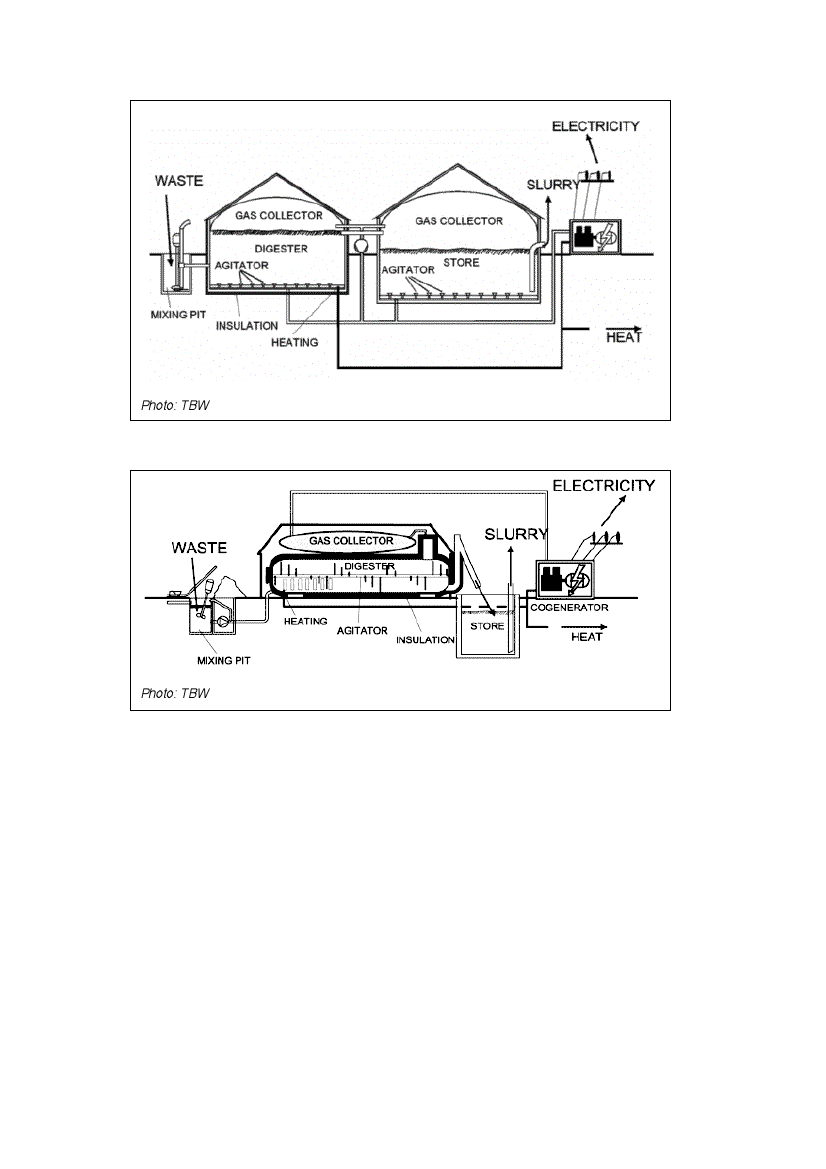

Figure 13: Concrete digester with integrated plastic gas-holder

Photo: TBW

Figure 14: Steelvessel fermenter with seperate ballon gas-holder

Photo: TBW

Selection of appropriate design

In developing countries, the design selection is determined largely be the prevailing design in

the region, which, in turn takes the climatic, economic and substrate specific conditions into

consideration. Large plants are designed on a case-to-case basis.

Typical design criteria are:

Space: determines mainly the decision if the fermenter is above-ground or underground, if it

is to be constructed as an upright cylinder or as a horizontal plant.

Existing structures may be used like a liquid manure tank, an empty hall or a steel

container. To reduce costs, the planner may need to adjust the design to theses existing

structures.

Minimizing costs can be an important design parameter, especially when the monetary

benefits are expected to be low. In this case a flexible cover of the digester is usually the

cheapest solution. Minimizing costs is often opposed to maximizing gas yield.

Available substrate determines not only the size and shape of mixing pit but the digester

volume (retention time!), the heating and agitation devices. Agitation through gas injection is

16