nominal dimensions of 1/2" or 3/4" are adequate for small-to-midsize plants of simple design

and pipe lengths of less than 30 m. For larger plants, longer gas pipes or low system

pressure, a detailed pressure-loss (pipe-sizing) calculation must be performed.

When installing a gas pipe, special attention must be paid to:

• gas-tight, friction-type joints

• line drainage, i.e. with a water trap at the lowest point of the sloping pipe in

order to empty water accumulation

• protection against mechanical impact

Stirring facilities

Optimum stirring substantially reduces

the retention time. If agitation is

excessive, the bacteria have "no time to

eat". The ideal is gentle but intensive

stirring about every four hours. Of

similar importance is the breaking up of

a scum layer which has lost contact with

the main volume of substrate and is,

therefore, not further digested. This top

layer can form an impermeable barrier

for biogas to move up from the digester

to the gas holder.

As a rule of thumb it can be stated that

stirring facilities are more important in

larger plants than in small scale farm

plants.

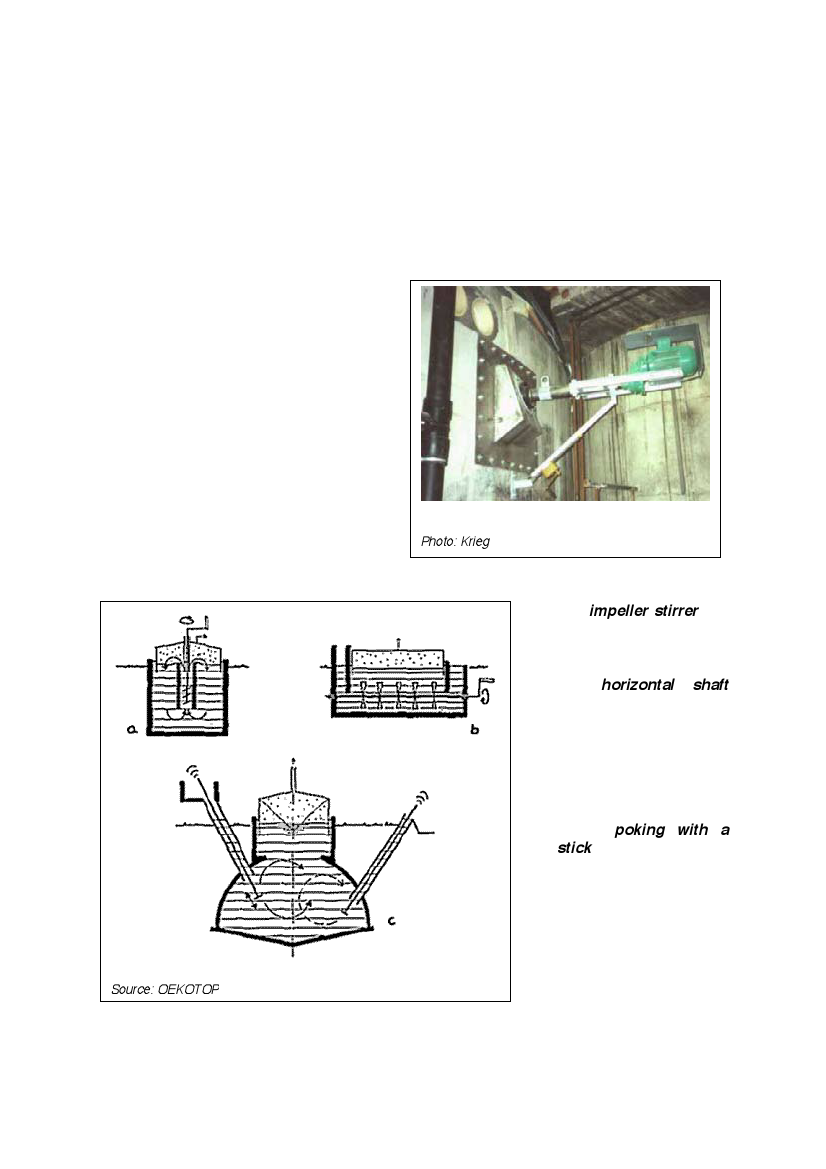

Figure 19: Stirring device for a european

biodigester

Photo: Krieg

Types of stirring facilities

a. The impeller stirrer has

given good results

especially in sewage

treatment plants.

b. The horizontal shaft

stirs the fermentation

channel without mixing

up the phases. Both

schemes originate from

large-scale

plant

practice.

c. For simple household

plants, poking with a

stick is the simplest and

safest stirring method.

Figure 20: Stirring facilities in the digester

Source: OEKOTOP

25