• Deenbandhu, the successor of the

Janata plant in India, with improved

design, was more crack-proof and

consumed less building material than

the Janata plant. with a hemisphere

digester

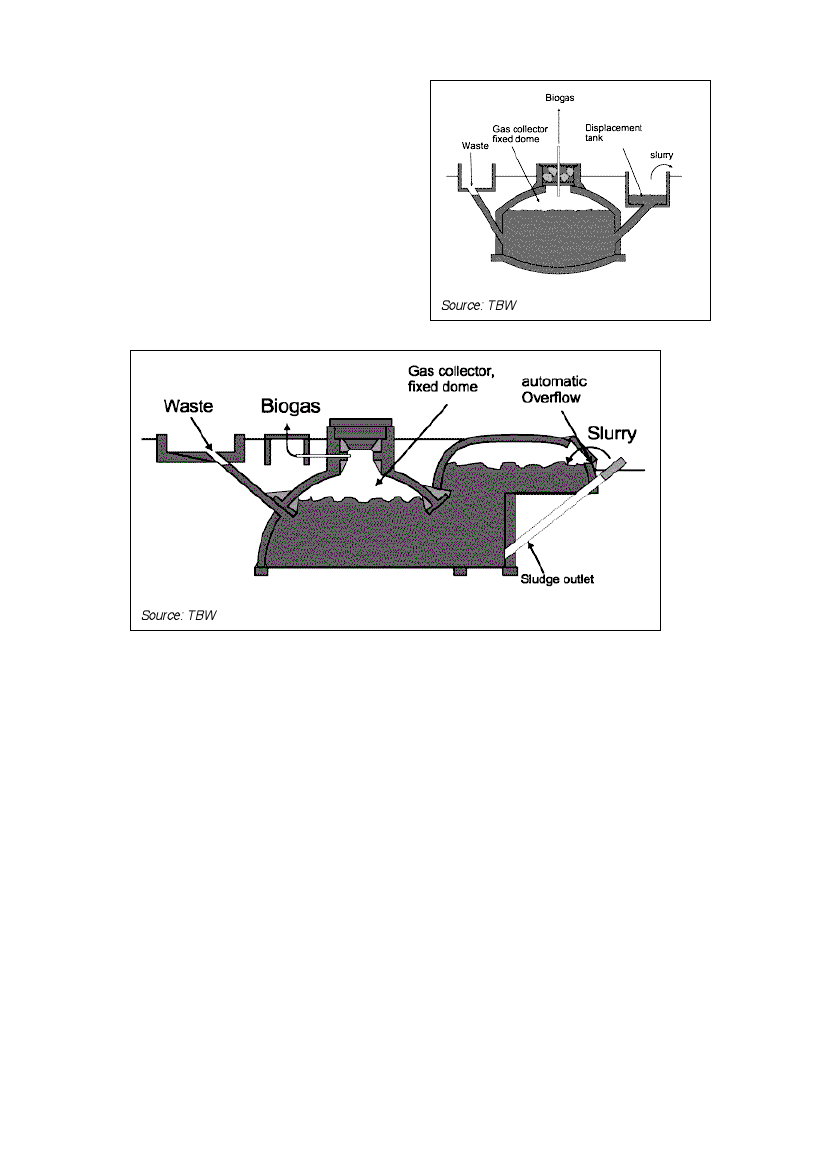

• CAMARTEC model has a simplified

structure of a hemispherical dome

shell based on a rigid foundation ring

only and a calculated joint of fraction,

the so-called weak / strong ring. It was

developed in the late 80s in Tanzania.

Figure 4: Chinese fixed dome plant

Source: TBW

Figure 5: Fixed dome plant CAMARTEC design

Source: TBW

Climate and size

Fixed-dome plants must be covered with earth up to the top of the gas-filled space to

counteract the internal pressure (up to 0,15 bar). The earth cover insulation and the option

for internal heating makes them suitable for colder climates. Due to economic parameters,

the recommended minimum size of a fixed-dome plant is 5 m3. Digester volumes up to 200

m3 are known and possible.

Advantages: Low initial costs and long useful life-span; no moving or rusting parts

involved; basic design is compact, saves space and is well insulated; construction

creates local employment.

Disadvantages: Masonry gas-holders require special sealants and high technical skills

for gas-tight construction; gas leaks occur quite frequently; fluctuating gas pressure

complicates gas utilization; amount of gas produced is not immediately visible, plant

operation not readily understandable; fixed dome plants need exact planning of levels;

excavation can be difficult and expensive in bedrock.

Fixed dome plants can be recommended only where construction can be supervised by

experienced biogas technicians.

10