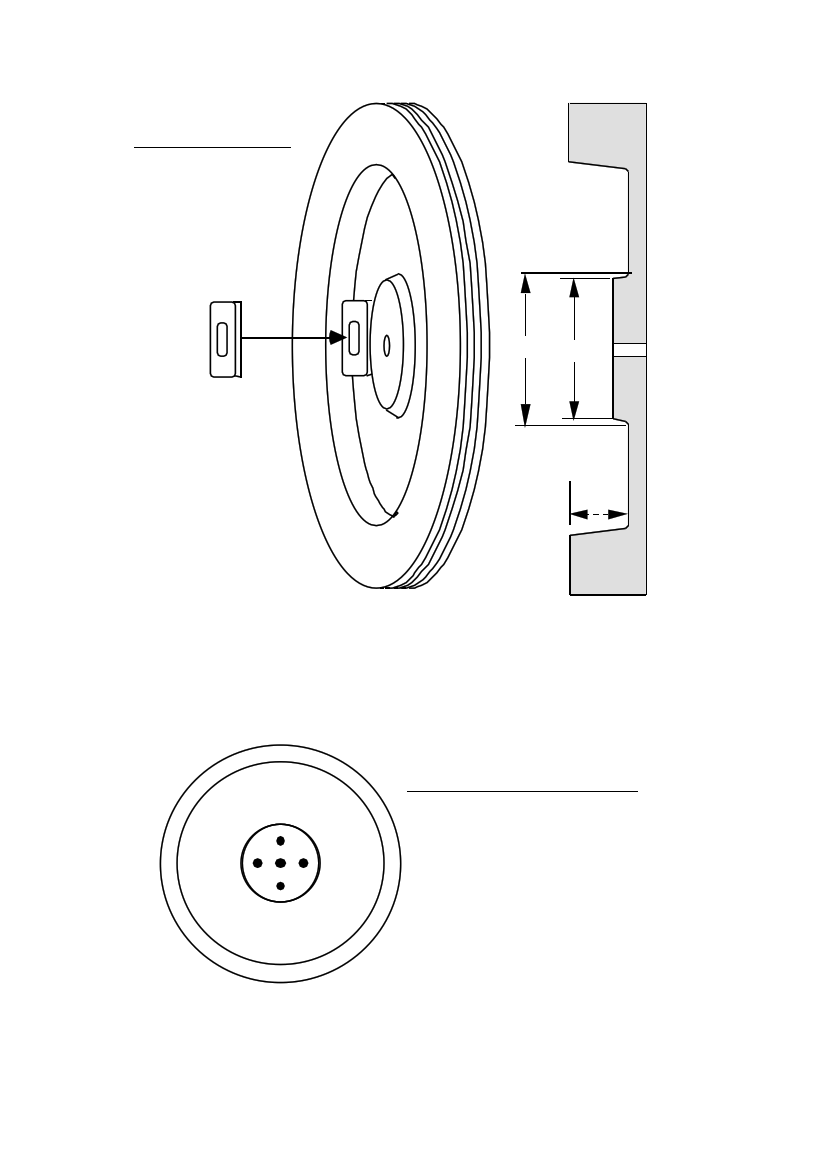

18. CENTRE DISK

SECTION

CHECK THAT

THE COIL FITS

COMFORTABLY

140 130

HOLE

60

• Place a coil against the face of the mould and check that it fits comfortably - if

not, then the hollow must be made a little larger, or the centre disk a little

smaller. In the end, the coil's centre must be at 250 mm from the mould centre.

• Remove the mould from the lathe or motor.

19.HOLES IN THE MOULD

Drill four holes in the central part which are used to separate the two moulds

(diagram 19). Screw some small pieces of plywood onto the underside of the mould

to make 'feet'.

PMG manual

page 19

June 2001