Intermediate Equipment Handbook

Intech Associates

At low utilisation of the equipment, the finance and depreciation costs can

overshadow operating costs as overall unit costs rise substantially.

In the UK it is expected that heavy plant will be used between 1,500 and 2,000

hours a year to be economic for the owner (Figures 1.7 and 1.8).

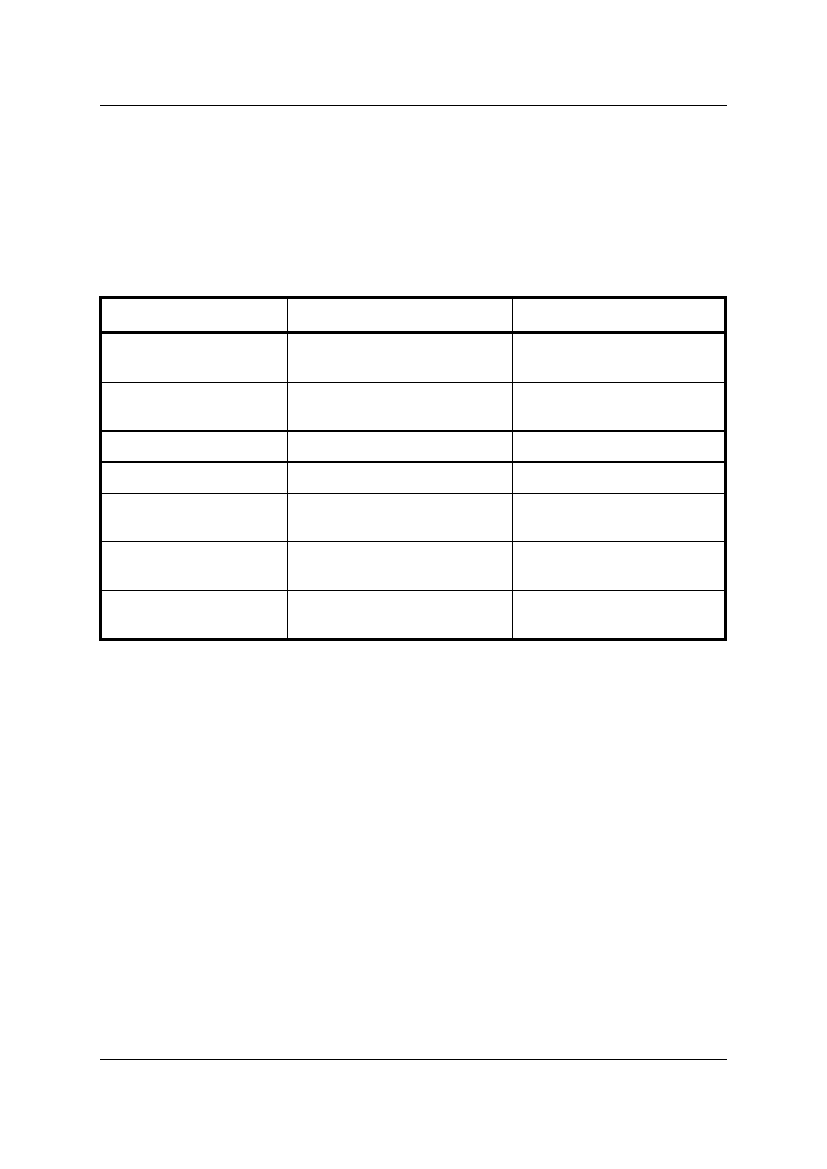

Figure 1.7 ECONOMICAL OWNERSHIP PERIODS FOR HEAVY PLANT - UK

PLANT ITEM

ECONOMIC LIFE - YEARS USAGE - HOURS/YEAR

LARGE HYDRAULIC

EXCAVATORS

9

1,575

DOZERS/SCRAPERS/

(GRADERS?)

10

1,680

LOADERS/SHOVELS

9

1,680

TIPPER TRUCKS

6

1,890

ROLLERS/

COMPACTION

6

1,680

DIESEL ROAD

VEHICLES

6-7

1,890

PETROL ROAD

VEHICLES

5-6

Source: Spon’s Civil Engineering & Highway Works Price Book, 1997.

1,890

Contractors and road authorities in developing countries can find it difficult to

approach these levels of utilisation for their road construction and maintenance

activities for various reasons. These factors include limited workloads for

individual specialist equipment items, seasonal factors, shortage of funds to

support the operations or cash flow discontinuities, low availability of equipment

(age, support problems), lack of performance incentives, the road network

logistics.

Where records exist, utilisation rates of well below 1,000 hours per year can be

experienced. This seriously affects unit operating costs.

In view of these figures it would be sensible for contractors, road authorities and

investors to consider commercially operated equipment hire companies to

ensure that any equipment investment is being utilised by somebody.

Intermediate equipment with flexible applications across a number of sectors will

offer greater chances of achieving high utilisation and thus profitability.

October 2012

41