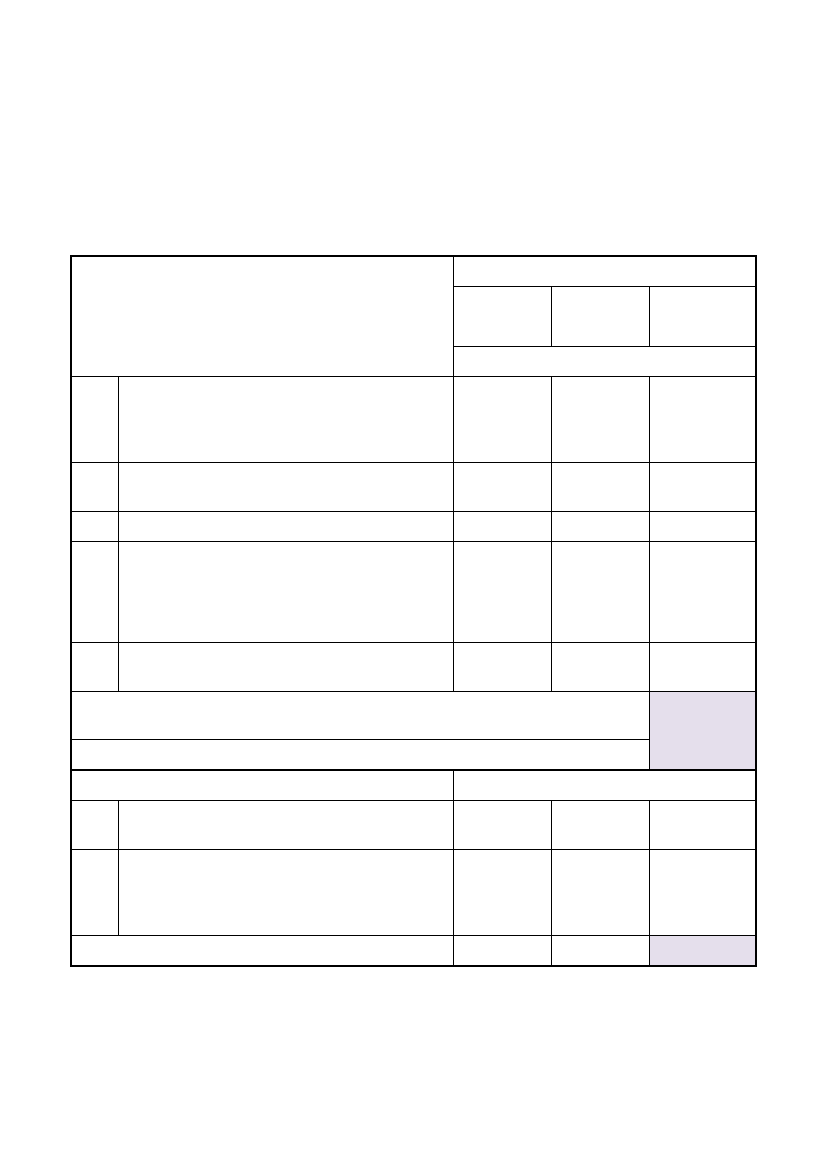

APPENDIX 2 – THE COST OF LOSS OF STANDARDISATION

NOTE: This example is taken from a situation where it is proposed to expand an existing tractor

fleet of 10 No. identical tractors to a total fleet of 20 No. tractors.

The two options are to procure a further 10 No. of the same standard models, or procure 10 ‘non

standard’ units of a different manufacturer/model.

The organisation handles its own spare parts storage, and tractor repair. The purchase price of the

tractors is taken as £12,000.

ADDITIONAL INITIAL INVESTMENT

ITEM

STANDARD

MODELS

NON

STANDARD

MODELS

ADDITIONAL

COST

£ (STERLING )

ADDITIONAL SPARE PARTS REQUIRED FOR STOCK TO

MAINTAIN PRESENT LEVEL OF COVERAGE (BASED ON

1 STOCK HOLDING OF 10% OF REPLACEMENT VALUE PER

UNIT FOR 10 UNITS, AND 8% FOR 20 UNITS)

7,200

12,000

4,800

ADDITIONAL FLOOR SPACE, AND/OR RACKING AND BINS

2 FOR PARTS STORE

400

2,000

1,600

3 ADDITIONAL SPECIAL TOOLS REQUIRED

1,600

1,600

ADDITIONAL TRAINING

4 EXTERNAL – EXPENSES FOR 1 MECHANIC FOR 2 WEEKS

INTERNAL – 20 MAN DAYS @ £10/MAN DAY

INCREASED STOCKING OF LUBRICATING OIL (3 X 45

5 GALLONS

400 400

200 200

400 400

TOTAL ADDITIONAL INVESTMENT REQUIRED IF NON STANDARD UNITS

PURCHASED

9,000

(EXPRESSED AS % OF PURCHASE COST OF TRACTORS)

7½%

ADDITIONAL ‘ON-GOING’ COSTS (P.A.)

STOREMAN MADE UP TO FULL TIME ON STORES WORK

1 (I.E. ADD 2 DAYS/WEEK)

1,000

1,000

ADDITIONAL COST OF PROCUREMENT (MORE SMALL

ORDERS – LOSS OF DISCOUNTS, INCREASED COSTS OF

2 CARRIAGE) ESTIMATED AT 5% OF SPARES COSTS

(£20,000 P.A.)

1,000

1,000

TOTAL ADDITIONAL ‘ON-GOING’ COSTS (P.A.)

2,000

SOURCE: Developed from ‘The Specification of Agricultural Machinery for use in Developing

Countries, A. A. Metianu, Silsoe, for ODA, 1979’.

A2-1