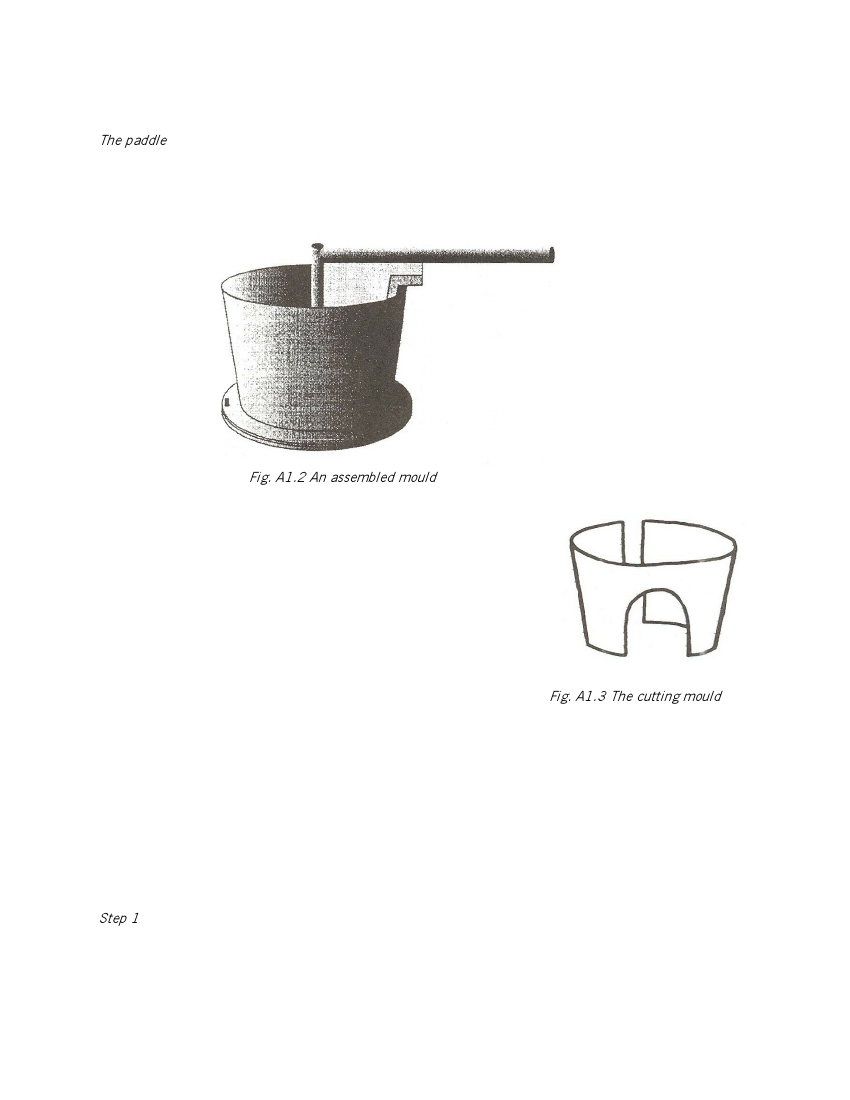

The paddle

This is made up of two pieces of steel pipe welded together at right- angles so that the vertical paddle stem

fits over the stem on the base plate. The horizontal pipe is the paddle handle. A steel blade is welded

between the pipes. The outer edge of the blade is curved to one side at an angle of 45°. This is designed to

squeeze the clay against the mould body as it is moulded.

Fig. A1.2 An assembled mould

The cutting mould

The cutting mould is made from sheet-steel cut in the same shape as the

conical section of the mould body. The door shape is also cut out. It is

rolled but not welded closed, and can be made from much thinner sheet.

Fig. A1.3 The cutting mould

The pot-rest mould

The pot-rest mould can be made of either plaster or cement. Cement is usually cheaper and more durable.

To make a cement pot-rest mould you will need:

• clay

• approximately 1 kg of cement powder

• an equal amount of fine sieved sand

• some soap

• a little water

• a plastic box that is about 25 cm long, 15 cm wide and 10 cm high, or a small cardboard box and

some polythene

Step 1

Make a "perfect" pot-rest by hand (or using a mould if you can borrow one). Try it on a stove but do not fix

it to the stove. Lay your perfect pot-rest flat.